Singapore

MMA/PMMA

Our MMA Plant and PMMA Plant (SUMIPEX®) are both located on Jurong Island with vertical integration from raw material to product and customers. Raw materials are available through pipelines as well as bulk imports.

SUMIPEX® is the registered trademark of Sumitomo Chemical for its PMMA resins, manufactured in Singapore with a 150,000MT annual production capacity. Sumitomo Chemical Asia is one of the largest PMMA producers in Asia.

Location: SMAG @ Sakra, Jurong Island, Singapore

Opened: Since 1996

Production capacity

MMA Monomer: 223,000MT

PMMA Polymer (SUMIPEX®): 150,000MT

Production Process

MMA Monomer: C’4 Oxidation

PMMA Polymer (SUMIPEX®): MMA-m Bulk Polymerization

S-SBR

Our first synthetic rubber plant outside Japan is located on Jurong Island of Singapore. Sumitomo Chemical’s S-SBR has consistently earned high praises from customers in the tyre manufacturing industries both in Japan and overseas for being a highly fuel-efficient tyre material with outstanding abrasion resistance. Building on this reputation, our Singapore S-SBR plant has already become one of the primary suppliers of synthetic rubber to tyre manufacturers and factories in Asia.

Location: Merbau, Jurong Island, Singapore

Opened: 2010

Production capacity per annum:

Styrene-butadiene rubber (40,000 tons)

Production process: Solution polymerisation

Plant Information

| First Plant (SMP-I) | 50,000MT per year |

| Second Plant (SMP-II) | 50,000MT per year |

| Third Plant (SMP-III) | 50,000MT per year |

| Total Capacity | 150,000MT per year |

Products

SUMIPEX® (SUMIPEX® PMMA Moulding Resins)

Types of Packaging:

- 25Kg Paper Bag

- 25Kg Resin Bag

- 750Kg Flexicon Bag

- 19000Kg Seabulk

Process:

Our plants adopt a safe and compact process, which can produce a wide range of product grades from high fluidity resin to low fluidity resin.

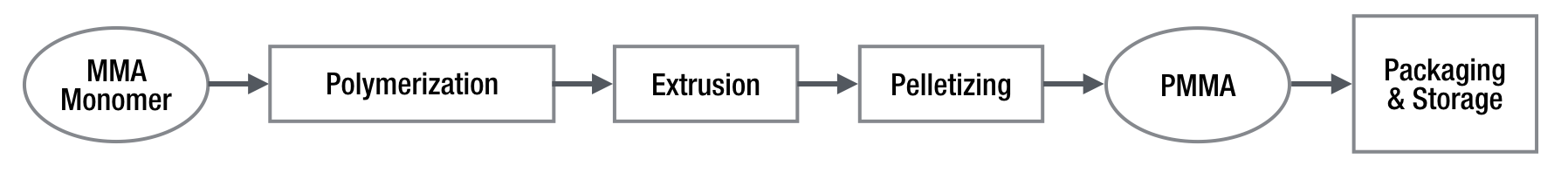

Poly Methyl Methacrylate polymer is manufactured by continuous bulk polymerisation of MMA-Monomer. The process is simple, compact, and is highly efficient due to the vertical integration of the MMA and SUMIPEX® PMMA plants. Applications of SUMIPEX® PMMA polymer include general purpose, lens manufacturing, extruded sheets, LCD applications, etc.

Our plants’ utilisation of state-of-the-art manufacturing technologies, together with continual technical support from Sumitomo Chemical, strive to maintain consistent production of high quality products to achieve superior customer satisfaction.

The flow chart below summarises the production process of SUMIPEX® PMMA polymer.

Plant Information

| First Plant (SMM-I) | 53,000MT per year |

| Second Plant (SMM-II) | 80,000MT per year |

| Third Plant (SMM-III) | 90,000MT per year |

| Total Capacity | 223,000MT per year |

Products

Main Product: MMA monomer

Process

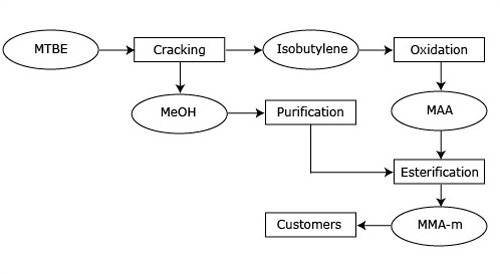

Methyl Methacrylate Monomer is manufactured by oxidation of isobutylene. The process does not use any toxic raw material and does not produce waste acid by-products. Applications include cast sheets, plastic modifiers, emulsions for paints/adhesives, etc. MMA is also used as a raw material for SUMIPEX® PMMA Polymer.

Our plants are constructed based on Sumitomo Chemical’s innovative technology and state-of-the-art manufacturing processes. In addition, it is a safe and reliable process that does not utilize any highly toxic raw materials. It is also capable of producing monomers that are suitable for optical grade polymers.

The flow chart below summarises the production process: